Fine Heat Treaters

Fine heat treaters is formerly known as heat well. Fine Heat Treaters is a small-scale industry, established in 1999. By promoter by Mr. K. Gopinath. who are highly experienced in Heat Treatment and Tool Room Technology.

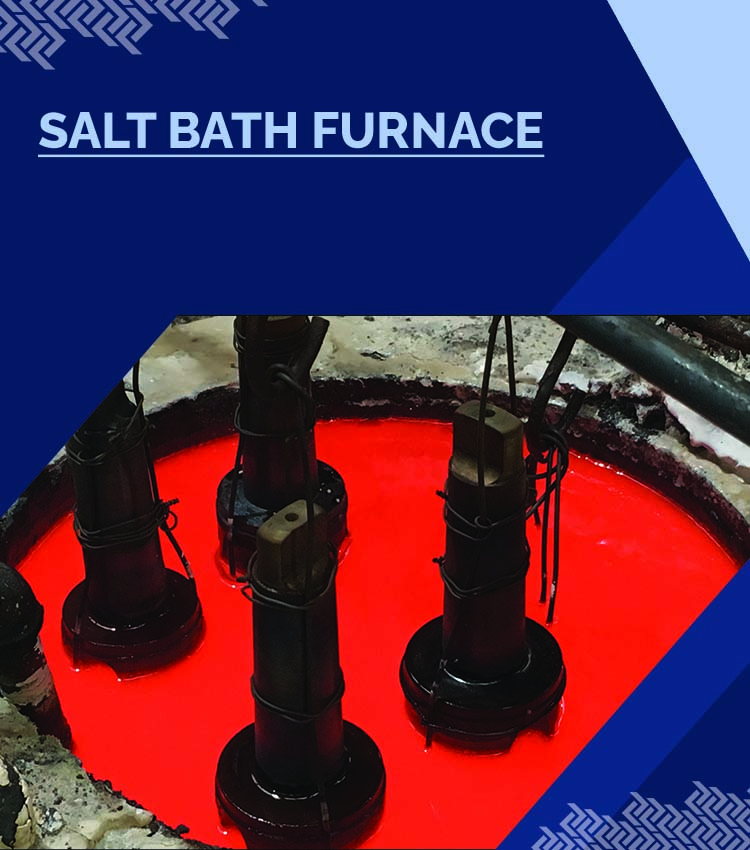

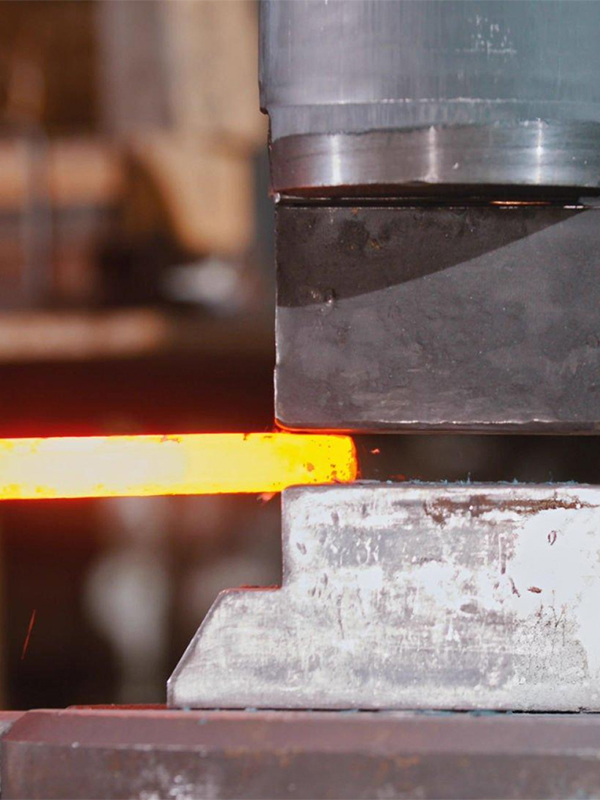

The Company has specialized in the heat treatment of tool and alloy steel, such as HSS, HDS, HCHCR, OHNS and other tools steels, that are commodiy used in tool room work. It is a tailor-made heat treatment unit for tool rooms and manufacturers of cutting tool, cold forging tools, press tools and hot forging dies.

Heat Treatment of high-speed steel, which is a highly specialised area, calling for high degree of knowledge and experience, is our forte. We are market leaders in this area in Bangalore. In addition, we have customers from Chennai, Coimbatore, Mysore, Hyderabad, Hubli and Pune.

Expert Team

Members

Safe

Solutions

Works in 4 Simple Steps

Assessment

We evaluate the material and determine the most suitable heat treatment process.

Preparation

We prepare the material according to the chosen process to ensure optimal results.

Processing

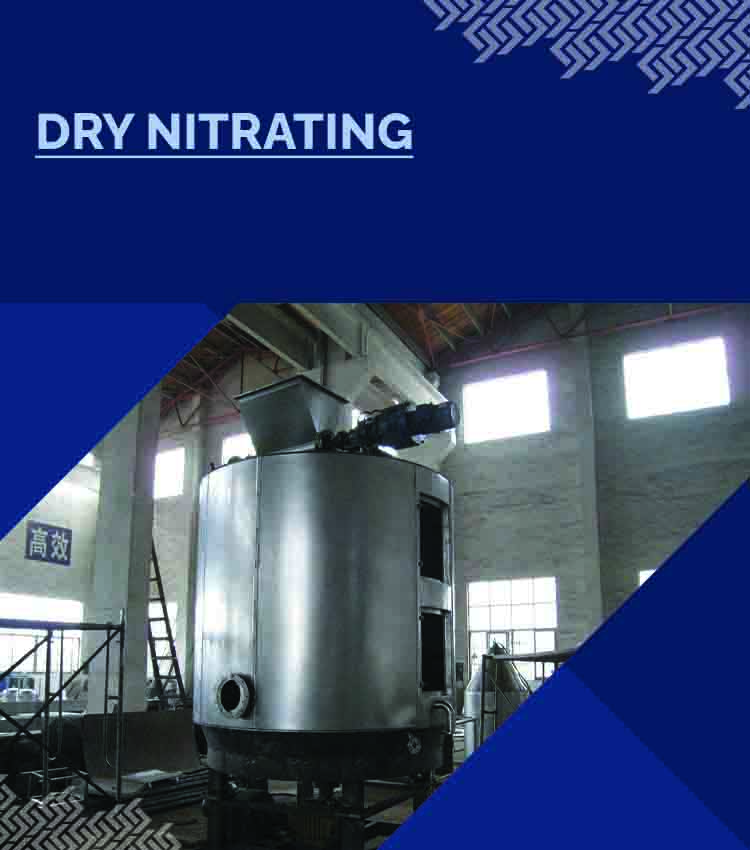

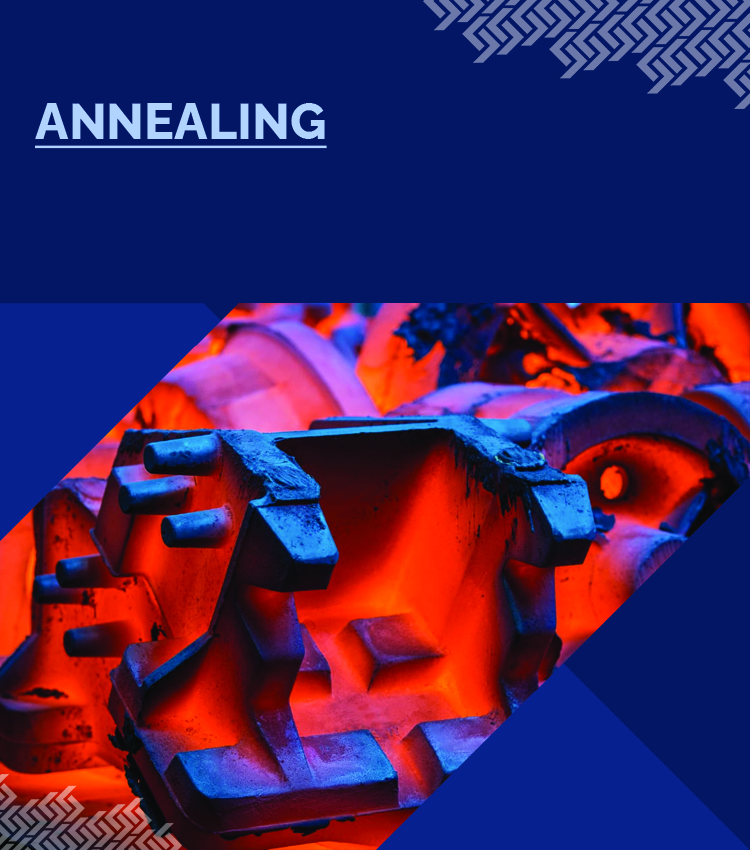

We perform the heat treatment process, such as annealing, normalizing, or Nitrating.

Inspection

We conduct a thorough inspection to ensure the material meets all specifications.

Our Recent Heat Treatment Projects

Years Of Experience

Projects Completed

Happy Customer

Team Members

Our Recent Projects

Here is Some Clients Feedbacks

Any Question

-

What is Fine Heat Treaters?Fine Heat Treaters is a leading service-based company specializing in advanced heat treatment processes for various metals and alloys. We provide expert solutions for annealing, normalizing, hardening, tempering, and Nitrating to improve the mechanical properties of materials for various industrial applications.

-

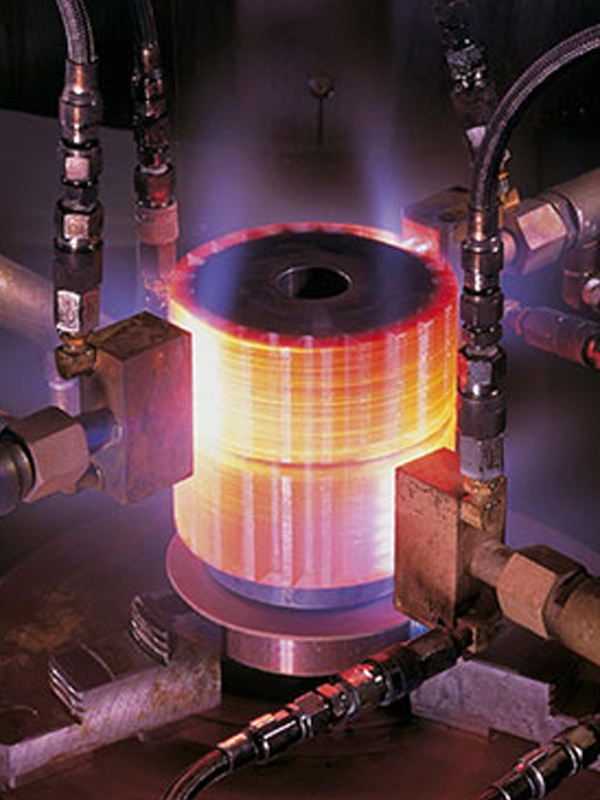

What is hardening and why is it important?Hardening is a process that increases the hardness and strength of metals by heating them to a specific temperature and then rapidly cooling them (quenching). This process is essential for components that need to withstand high levels of wear and stress, such as cutting tools, gears, and bearings.

-

Difference Between Salt Bath and Vacuum?Salt bath and vacuum heat treatments are two distinct methods used to alter the properties of materials, particularly metals, through controlled heating processes.